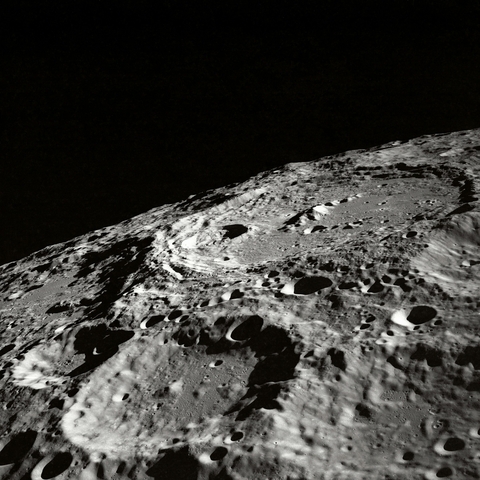

- Our most urgent task was to engineer a robust, safe, and low-energy solution to safeguard the electronics of the Lunar Rover from freezing during the extreme cold of lunar nights. Failure to do so risks shutting down vital systems, putting the entire mission in jeopardy.

- But our engineers' work didn’t end there. To truly push the boundaries of space exploration, they had another objective: Deliver a system to research and monitor battery behavior in the deep space vacuum. This would provide essential data to ensure the success of future missions, venturing even further into the unknown.

Driving NASA's Lunar Rover: The Power of Printed Heaters and Battery Monitoring Solution

Case Study

A NASA lunar rover must endure extreme conditions on the Moon, including dramatic temperature shifts, intense radiation, and rugged terrain. It is essential to maintain the functionality of the rover's components during the frigid lunar night and ensure a consistent and reliable power supply in this harsh environment. The rover's survival and mission success on the Moon hinge on advanced technologies. Discover how FLEXOO successfully supported and persuaded NASA with its innovative solutions.

Key challenges faced by our customer NASA:

- Overcoming the challenge of maintaining reliable battery performance in the Moon's vacuum, where extreme temperatures can affect power stability.

- Developing solutions to prevent electronics from freezing.

- Ensuring precise temperature control in the harsh lunar environment.

Sought-after solutions should not only ensure protection, but also maximize performance:

- Ensuring the Rover's components function within safe parameters, providing critical insights into system integrity.

- Getting immediate access to sensor data, enabling quick decision-making and adaptive responses during the mission.

- Minimizing energy consumption with a compact solution while ensuring the safety and durability of the Rover's electronics.

- Maintaining necessary temperatures with minimal energy use, preserving battery life for extended missions.

- Engineering against the freeze: We provided a set of PTC heaters containing an anti-freeze solution for additional testing in a climate chamber set to experience extremely low sub-zero temperatures.

- Maximizing the performance: We provided our cutting-edge BaMoS system designed to accurately measure the temperature and pressure distribution of pouch batteries within a vacuum environment.

Still unsure? Here are four convincing reasons why we satisfied our customer:

- PTC heaters are thin, flexible, and durable, making them easily integrated into your existing designs.

- Heating mats are designed to operate with low voltage, ensuring the safety of electronic systems thanks to their self-limiting capabilities.

- BaMoS system enables real-time monitoring of pressure and temperature distribution within the battery pack, ensuring optimal performance and safety of the batteries.

- Gathering data from battery tests is crucial for maximizing charging efficiency and understanding the behavior of pouch batteries during charging and discharging in a vacuum environment.

What's Next? Paving Your Way Forward

- Contact Our Sales Team Ready to take the next step? Reach out to our sales team today to schedule an appointment with our dedicated sales manager. read more

- BaMoS In various industries, batteries serve as vital components, powering a wide array of applications. read more

- Foil Heaters Flexible foil heaters, available in PTC and fixed power variants, offer customized heating solutions for diverse applications. read more

Let’s Start to Work on Your Challenge!

Ready to take the next step? Reach out to our sales team today to schedule an appointment with our dedicated sales manager and discover how we can tailor our solutions to meet your needs.